Core Mechanics of Classic Car Carburetors

Classic car engine technology relies heavily on carburetor mechanics to mix air and fuel efficiently for combustion. The fundamental principle of a carburetor’s operation is based on the Venturi effect—air passing through a narrowed section creates suction, drawing fuel into the airflow. This precise balance of air and fuel is essential for engine performance.

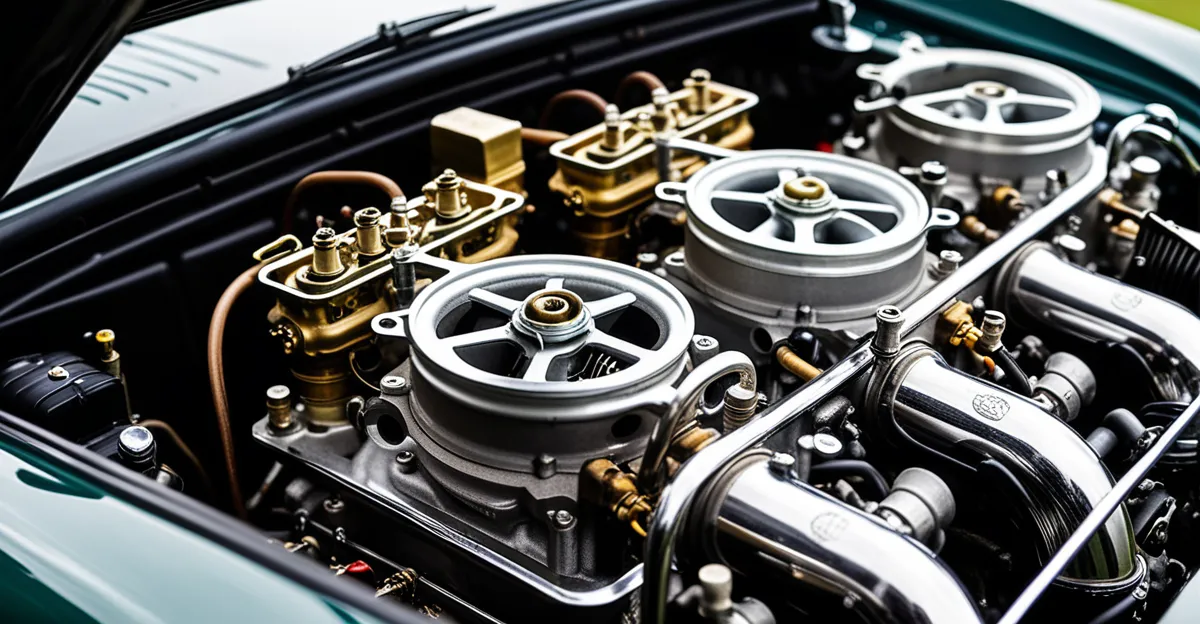

Key components include the float chamber, which regulates fuel level; jets, controlling fuel flow; and the throttle valve, managing air volume entering the engine. Each part influences power delivery and responsiveness. Classic carburetors often use needle valves and choke mechanisms to adjust mixture richness during different engine conditions, such as cold starts.

Topic to read : Comprehensive Handbook for Assessing and Guaranteeing Steering System Safety in UK Automobiles

In the UK, several classic car carburetor models stand out. For example, the SU carburetor uses a variable venturi to maintain optimal mixture, differing from fixed-jet designs. Meanwhile, the Solex and Stromberg models each feature unique jet configurations affecting tuning and fuel efficiency. Understanding these carburetor mechanics helps in appreciating how classic engines deliver their characteristic driving experience and enables better maintenance and performance tuning.

Core Mechanics of Classic Car Carburetors

Understanding the function of carburetors requires a detailed look at carburetor mechanics and their role in classic car engine technology. Carburetors operate by managing the airflow and fuel mixture to optimize combustion. The Venturi effect is central—air moving through a narrowed tube speeds up, lowering pressure and causing fuel to be drawn into the airstream.

Key components influence this process: the float chamber regulates fuel supply, preventing flooding or starvation. Jets control fuel delivery’s volume and atomization, impacting power and economy. The throttle valve adjusts airflow to the engine, directly affecting acceleration and engine speed.

Among common UK classic car carburetor types, notable differences affect tuning. For example, the SU carburetor’s variable venturi adapts to changes in throttle position, delivering a more consistent mixture across speeds. In contrast, Solex carburetors use fixed jets that require precise tuning for each operating condition. Stromberg models often combine features of both, offering unique performance characteristics ideal for particular British classic cars. This mechanical diversity shapes how these engines respond, highlighting the importance of mastering carburetor mechanics for optimal classic car engine technology performance.

Core Mechanics of Classic Car Carburetors

Carburetor mechanics form the backbone of classic car engine technology, directly affecting how air and fuel combine for combustion. At its core, the function of carburetors hinges on controlling air velocity and fuel flow through the Venturi effect. This interplay determines engine power, fuel efficiency, and responsiveness.

Key components include the float chamber, jets, and throttle valve, each playing a specific role. The float chamber stabilizes fuel supply, ensuring a steady flow when the throttle opens. Jets meter fuel quantity precisely, shaping the air-fuel ratio critical for combustion quality. Meanwhile, the throttle valve regulates airflow into the engine, orchestrating power output during acceleration or cruising.

Among UK carburetor models, variations in design impact tuning and performance. The SU carburetor’s variable venturi adapts fuel mixture automatically with throttle changes, making it popular in British classics for smooth operation. Solex models rely on fixed jets, requiring careful tuning but offering reliability. Stromberg carburetors blend these approaches, providing flexibility well-suited for diverse driving conditions. Understanding these carburetor mechanics is essential for optimizing the unique characteristics of classic car engine technology.

Core Mechanics of Classic Car Carburetors

The function of carburetors revolves around precisely managing the air-fuel mixture to optimise combustion in classic car engine technology. At its core, carburetor mechanics rely on the Venturi effect: as air accelerates through a narrowed passage, pressure drops, creating suction that draws fuel into the airflow. This fundamental principle ensures the engine receives the correct mixture for efficient burning.

Key components play crucial roles in this process. The float chamber maintains consistent fuel levels, preventing flooding or starvation. Jets meter the fuel flow, finely tuning the air-fuel ratio essential for smooth operation. The throttle valve controls the amount of air entering the engine, directly impacting power output and responsiveness.

UK classic carburetor models illustrate variations in design and function. The SU carburetor’s variable venturi adjusts automatically to throttle changes, maintaining mixture consistency across different speeds. Solex models use fixed jets, necessitating careful tuning to match conditions. Stromberg carburetors combine these traits, offering versatility that suits a range of British classic cars. Understanding these carburetor mechanics deepens appreciation of how different designs affect performance in classic car engine technology.

Core Mechanics of Classic Car Carburetors

The function of carburetors in classic car engine technology relies on a precise balance of air and fuel to ensure optimal combustion. Central to carburetor mechanics is the Venturi effect, where air velocity increases through a narrowed passage, creating a pressure drop that draws fuel into the airflow. This mechanism directly influences engine performance by regulating the air-fuel mixture.

Key components dictate this process: the float chamber ensures a steady fuel supply, preventing overflow or starvation. Jets measure fuel quantity, crucial for maintaining the correct ratio needed for efficient burning. The throttle valve adjusts air intake, controlling power output as driver demand changes.

Differences among common UK classic car carburetor models reflect design philosophies affecting tuning and engine response. The SU carburetor uses a variable venturi that automatically adapts to throttle position changes, offering smooth mixture control across speeds. In contrast, Solex carburetors rely on fixed jets, requiring precise manual tuning to suit specific conditions. Stromberg carburetors merge aspects of both designs, providing a flexible setup well matched to diverse British classic car engines.

Understanding these carburetor mechanics illuminates how the function of carburetors shapes the distinctive performance of classic car engine technology.